From Integrated Engineering to Integrated Operations and Services: digitized solutions along the entire value chain make glass plant operators and equipment suppliers more efficient, more flexible, better and faster. Digitalization will change the face of the glass industry as much as electrification and automation did in earlier times. The result will be huge leaps in productivity.

Introduction

A Europe-wide study [1] by German industry association VDMA and McKinsey forecasts that more than ten percent of revenue in the mechanical engineering industry alone will be generated using data-based business models by 2020 (Figure 1). Open standards, powerful communication networks and integrated automation and drive technologies are also of great importance to the glass industry in this regard, as it heads toward Industrie 4.0.

Figure 1: Data-based business models are also becoming increasingly relevant to the glass industry.

Main text

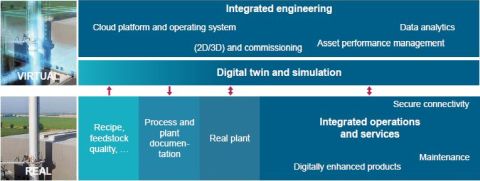

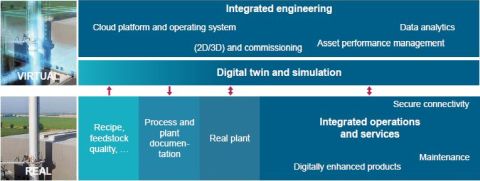

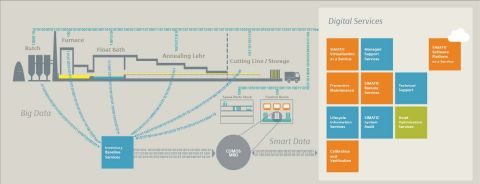

What does it actually mean when plant operators and equipment suppliers in the glass industry digitize their businesses? “In figurative terms we think of two directions, horizontal and vertical,” explains Bernhard Saftig, head of Glass Business, Process Automation, at Siemens in Karlsruhe.

“Horizontal refers to the digitalized value chain, which is why we say ‘From Integrated Engineering to Integrated Operations and Services,’ to describe consistency throughout the process – from designing the production facility and engineering to commissioning and operation, and the necessary services.” In the vertical direction, on the other hand, “Integrated Operations” describes the link between the real and the virtual worlds in the operating phase, in other words the connection between the field, automation and management levels, all the way to the Cloud.

Digitizing the value chain, step by step

Anyone dealing with the digitalized value chain will observe that consistency always implies consistent data. Plant operators and equipment suppliers that use a standardized data platform like Comos to integrate their engineering stages reach the operating phase, and thus the market, much faster. The fact that multiple planning stages can be executed simultaneously saves both time and costs.

Digital twin: a virtual copy of the plant

The result of Integrated Engineering is what’s known as the “digital twin” – a virtual copy of all or part of the plant. At the heart of this digital twin is a consistent data model that operators and equipment suppliers can use to run plant simulations for training purposes, for example. In turn, the data gathered while the plant is in actual operation is fed back into the data model. This keeps the digital twin up to date and maintains it as a one-to-one representation of actual plant status throughout the entire life cycle.

Benefits of Integrated Engineering

A further benefit of the digital twin is that, even before the plant goes into real operation, operators and equipment suppliers can view it using 3D visualizations and even walk through it at a virtual level. This has the advantage that employees can be trained at an early stage and, for example, test whether all the vital parts of the plant are readily accessible.

Comos Walkinside is an example of software that makes these functions a possibility. Another example that shows the advantages offered by Integrated Engineering: at the click of a mouse, all the data relevant to automation can be transferred directly from an engineering and design tool like Comos into a process control system, such as Simatic PCS 7. This can save up to 60 percent of the time normally spent on configuring the automation structures. And working with consistent data also improves the quality of the engineering. Product data can also be easily and rapidly integrated at this point using libraries, and much more besides.

(...)

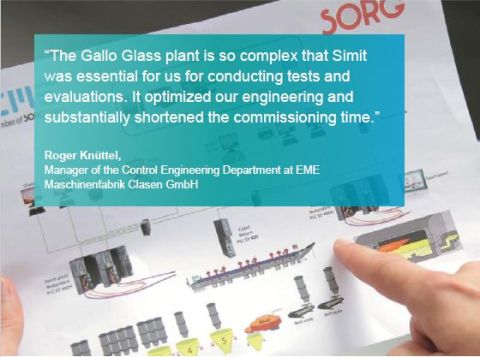

Benefits of Integrated Operations

Simulation software like Simit can also directly acquire automation data from the process control system and the engineering and design tool. This allows all automation and process control functions to be tested ahead of time, so potential faults can be rectified prior to real-world commissioning. This, too, saves time and costs, since the real commissioning process will then run smoothly and can take place much earlier, in parallel with further configuration work. The simulation software can also be used to provide early training to operating personnel. Testing can be performed to identify wiring or programming errors. And it makes work safer for the operating personnel.

During plant operation itself, too, changes in process control can be fed back into the engineering and design tool. That means you have access to up-to-date plant and process documentation at all times. A digital twin that is kept up to date saves time and costs, compared to documentation that has to be laboriously drawn up by hand or may not be available at all.

Maintenance and servicing are other aspects that are better resolved digitally during the operating phase: operators can use the process control system to convey their requirements directly and easily to the service personnel. If the service personnel use maintenance software like Comos MRO in conjunction with the opportunities offered by 3D visualization using Comos Walkinside, these requirements can be directly located and correctly assessed using the up-to-date plant and process documentation. The standardized database keeps all participants equally up to date, enabling them to arrange the necessary action in direct consultation. As a result, machines and devices can be kept perfectly maintained before any outages occur. The system works even faster if the employees can view the relevant information directly using tablet PCs. Here, too, the digital twin is brought up to date again once the process is complete.

Operations Intelligence, known as XHQ at Siemens, is another handy application in the operating phase: to make the best possible decisions, glass manufacturers must take data relating to the plant, process and economic efficiency into account. Operations Intelligence delivers all this data and these KPIs clearly and in real time, from all kinds of systems.

The data can be played back on customized cockpits or dashboards with the desired level of detail. This may involve an overview of particularly cost- intensive assets, for example. Or benchmark analyses in the plant. Or even global comparisons between different plants at different locations.

Benefits of Integrated Services

For services, too, digitized solutions prove handy: “Software as a Service,” for example. This means that equipment suppliers can obtain a time-limited license for specific software rather than purchasing it. They can then access a complete engineering environment via the Cloud, for example, without having to own and update it. Plant equipment suppliers benefit from having pre-tested packages they can use to perform these simulations, which again save time and money during the real commissioning process. Software-based employee training can also be provided ahead of commissioning.

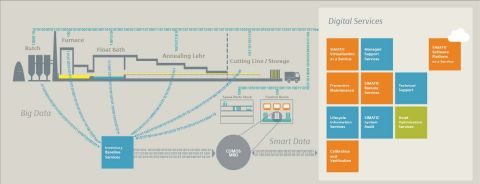

Cloud solution as a foundation for new, data-based business models

It is obvious that all activities containing the keyword “digitalization” will involve the use of a database. What’s new is that today, the data must be available everywhere, at all times, for quite different users, if all the various businesses involved are to benefit. Cloud solutions meet all these requirements. MindSphere is one example of a Cloud-based, open Industrial Internet of Things (IIoT) operating system. Being scalable, it supports the digital transformation of companies regardless of size or industry. It can be considered as a foundation for new, databased business models.

Anyone using the platform (“Platform as a Service – PaaS”) can improve plant performance, for example, by recording and analyzing large volumes of production data. This means MindSphere is the basis for applications and data-based services from Siemens and third-party providers, e.g. in the area of predictive maintenance, energy management, or resource optimization. At the same time, platform users benefit from a development environment in which they can integrate their own applications, services, and thus implement and offer new business models.

Smart Motors Cloud application

One of these applications involves the Smart Motors concept, a completely new generation of communications- capable drive technologies. The data recorded using integrated sensors (e.g. temperature or vibration data) can be read out quickly and easily and analyzed in Cloud environments. This means that users can improve both efficiency and plant availability, as well as optimizing their servicing and maintenance activities. For example, they can see that not all fan motors need to run at full speed if they are not currently needed. Converters can provide a simple solution here.

Defense in Depth

Anyone talking about the Cloud must also be able to provide state-of-the-art security concepts. To provide industrial plants with end-to-end protection against cyber attacks from both inside and outside, a simultaneous approach is needed at all levels, from operating level to field level, from access controls to copy protection. To do this, Siemens uses an in-depth defense structure – “Defense in Depth” – as an overarching protection strategy in accordance with the recommendations of ISA99/ IEC 62443, the leading standard for security in industrial automation.

Conclusions and Summary

“From Integrated Engineering to Integrated Operations and Services”: digitized solutions along the entire value chain make glass plant operators and equipment suppliers more efficient, more flexible, better and faster. Digitalization will change the face of the glass industry as much as electrification and automation did in earlier times. The result will be huge leaps in productivity. “Take the first step, start with a small, easy-to-follow data analysis and review the benefits. After all, there is no manual for digitalization. It needs daring players among the plant operators and equipment suppliers who are prepared to test things at a small level and then build up step by step to larger and larger tasks,” Saftig concludes.

The article is based on the lecture presented at the

GLASS PERFORMANCE DAYS 2017 Conference,

which took place on June 28-30, 2017

in Tampere, Finland

Bernhard Saftig

Siemens AG

References

[1] https://www.vdma.org/viewer/-/article/render/16241528

Całość artykułu w wydaniu drukowanym i elektronicznym

Inne artykuły o podobnej tematyce patrz Serwisy Tematyczne

Więcej informacji: Świat Szkła 03/2018